CS Instruments

- Robust and the lightweight

- Improved detection of leaks with optional acoustic trumpet

- Modern lithium-ion battery with high capacity, external recharger

- Minimum operating time 10 h Easy operation via keypad

- Find your leak size (l/min) and show the potential savings (£/year)

- Automatically adapts the sensitivity to the environment and eliminates ambient noise

- Photograph leaking parts

- Transmit leak details via USB to your desktop software or via Bluetooth to your app

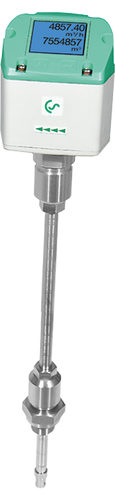

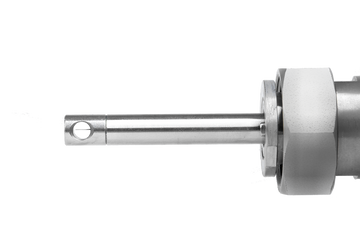

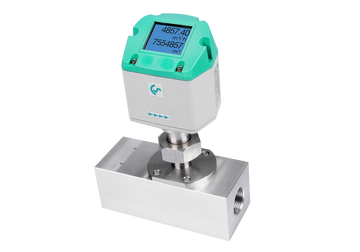

- Pressure Tight Up to 50 Bar

- Temperature Range Up to 110°c

- Protection Class Ip65

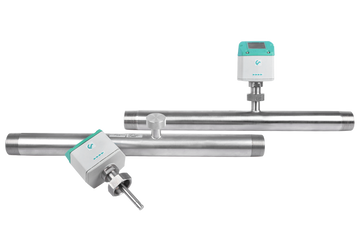

- Integrated Display for Showing the Measured Values

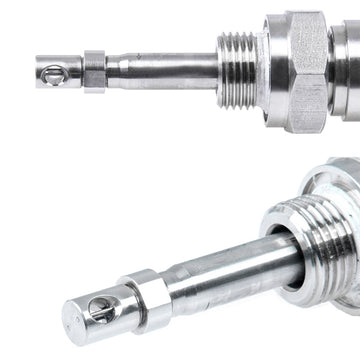

- Easy Installation Under Pressure

- Settings Can Be Changed via the Display

- Main Counter Reading Can Be Reset via the Display

- Suitable for Gas Velocities Up to 224 Nm/s

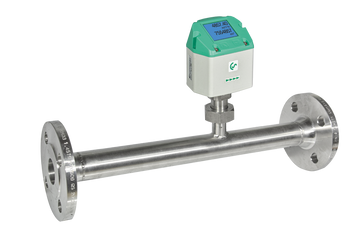

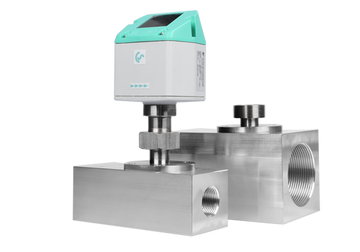

- Pressure Range Up to 40 Bar

- Temperature Range From -30 to 80°c

- Protection Class IP65 Integrated Display to Show the Measured Values

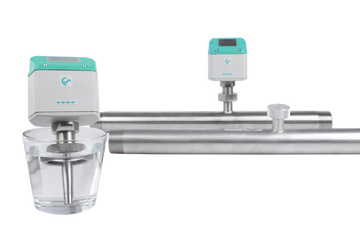

- Can Be Used From Dn 8 to Dn 80

- Settings Adjustable via the Keys of the Display

- Main Counter Reading Can Be Reset via the Display

- For Velocities Up to 224 Nm/s

- Optional Interfaces: Modbus Tcp (Ethernet), Poe, M-bus

- Pressure Range Up to 40 Bar

- Temperature Range Up to 80°c

- Integrated Display to Show the Measured Values

- Available From ½" to 2''

- Settings Adjustable via the Keys of the Display

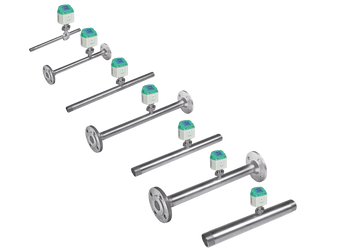

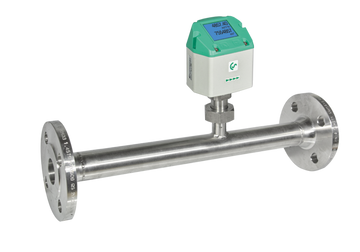

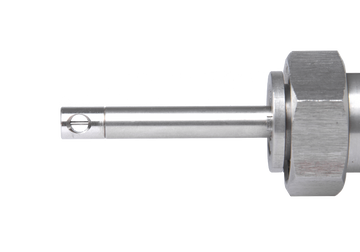

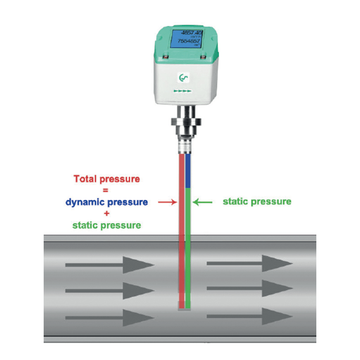

- Particularly suitable for extremely high flow rates

- Extremely fast response time: 100 ms

- Measures flow, total consumption, temperature and pressure

- Measurement at high temperatures – max. 200 °C

- Measurement in various gases by selecting gas type, on request

- Can be used in pipes from DN 20 to DN 500

- Installation via 1/2″ ball valve under pressure

- RS 485 interface (Modbus-RTU), 4…20 mA, pulse output as standard

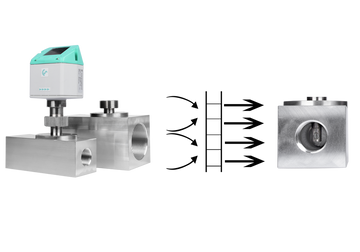

- Measurement of standard volume flow, operating volume flow, mass flow

- Measurement at high temperatures of up to 350°C

- Measurement up to 63 bar(g)

- Suitable for unknown/changing gas compositions and mixed gases

- Aggression resistant – all parts in contact with media made of stainless steel

- Not sensitive to vibrations due to reference vibration measurement

- No moving parts