Pressure Switches

A pressure switch is critical for regulating the activation and deactivation of pumps in fluid systems when pressure thresholds are reached. They are also used in process control systems to maintain consistent pneumatic or mechanical pressure.

Understanding how pressure switches work, the many types of pressure switches, and the typical applications for them can assist you in selecting the best solution for a specific application.

What is a Pressure Switch, Exactly?

A pressure switch is a simple electromechanical device operated by pressure to turn an electrical circuit on or off. The set point is the pressure threshold that activates the switch, while the cut out point is the pressure threshold that deactivates the switch.

A pressure switch is composed of the following parts:

- A diaphragm that also functions as a pressure sensor. It is often made of a pliable, pressure-sensitive substance.

- A spring with adjustability to vary the set or cut out points. Some switches have separate springs that control the set and cut out points.

- An AUTO/OFF lever. This lever is necessary for deactivating the switch during installation or maintenance. In other cases, a knob is used instead of a lever, but the concept is the same.

There are two kinds of pressure switches: normally open (NO) and normally closed (NC) (NC). The open/closed terminology refers to the switch's electrical contacts. When the pressure is within a safe range, the contacts in a NO switch stay open; when the pressure exceeds the safe limit, the connections close.

The application determines the pressure threshold that changes the state of the contacts in NC switches. It might be the set point for specific applications and the cut-off point for others.

What Purpose Does a Pressure Switch Serve?

A pressure switch is a passive device since it merely detects the presence or absence of pressure. The pressure of the diaphragm compresses a calibrated spring. When the spring tension approaches or exceeds a certain level, the contacts of a NO or NC switch are switched from open to closed.

For ease of setup across several applications, pressure switches generally comprise at least one pair of NO and one pair of NC contacts.

Applications for Common Pressure Switches

Pressure switches are commonly used in industrial process control systems. Here are a few such examples:

Systems that make use of compressed air. Pressure switches turn on or off the compressor at specific points.

HVAC units. Pressure switches are critical safety components in heating systems such as furnaces. They will turn off the furnace if they detect negative pressure caused by the draft-inducing motor. Pressure switches may detect leaks by measuring gas pressure.

Machines for processing. Pressure switches are used in fluid and gas flow control systems to maintain a consistent flow rate.

Pumping system. Pressure switches help to keep reservoir water levels stable by activating and deactivating the pump as required. The NO contacts shut when the water pressure falls below a particular threshold, enabling current to pass through the pump. When the water pressure surpasses the preset level, the contacts open, turning off power to the pump and, as a result, terminating the pumping activity.

PVL Pressure Switches

Pressure Vacuum Level Ltd has been selling high-quality pressure switches for over 28 years. PVL provides these devices for various industries.

Don't hesitate to contact us if you have any questions about our pressure switches or other products.

Other Products

PVL customers can rely on us for high-quality products. Pressure Switches are only a handful of the products we provide customers across the United Kingdom. We are also a significant supplier of Vacuum Switches and Transducers.

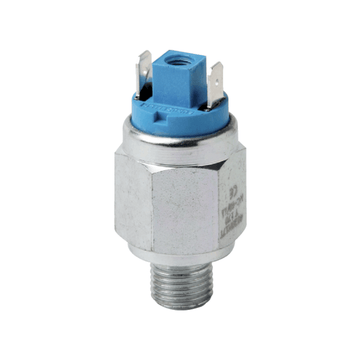

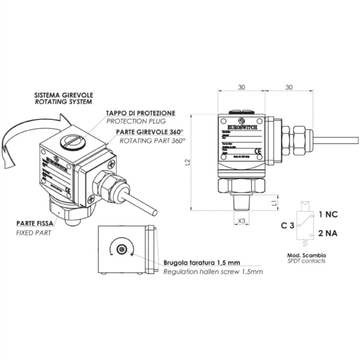

- Diaphragm Pressure Switch ≤ 48V

- N/O or N/C Contacts

- Up to 50 bar adjustment ranges

- Over-pressures up to 300 bar

- Max working pressures up to 150 bar

- 1/4” BSP thread (others available)

- Viton seal (others available)

- Brass, steel or stainless steel body

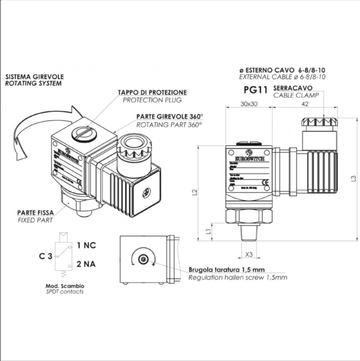

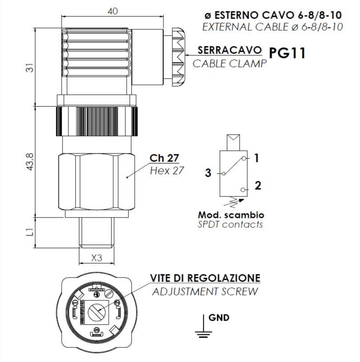

- Diaphragm Pressure Switch ≤ 250V

- SPDT C/O Contacts

- Up to 60 bar adjustment ranges

- Over-pressures up to 300 bar

- Max working pressures up to 150 bar

- 1/4” BSP thread (others available)

- Viton seal (others available)

- ATEX option available

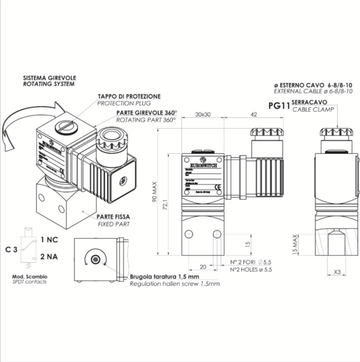

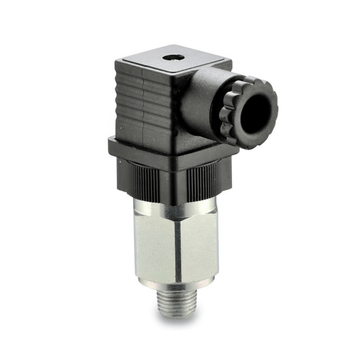

- Pressure Switch ≤ 250V

- SPDT C/O Contacts

- Up to 400 bar adjustment ranges

- Over-pressures up to 800 bar

- Max working pressures up to 450 bar

- 1/4” BSP male/female thread options

- Viton seal (others available)

- DIN43650 / cable options

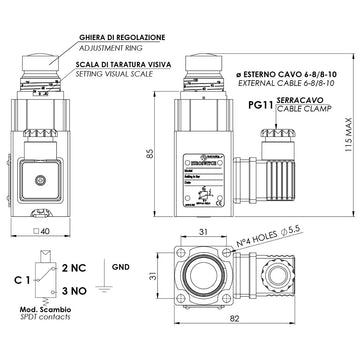

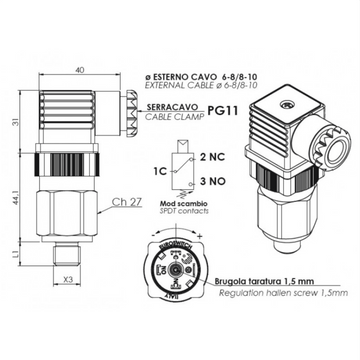

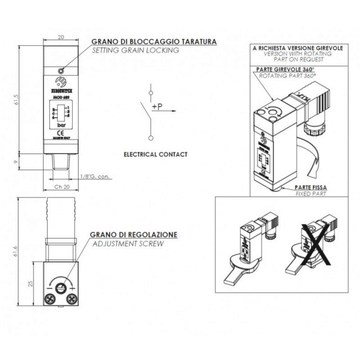

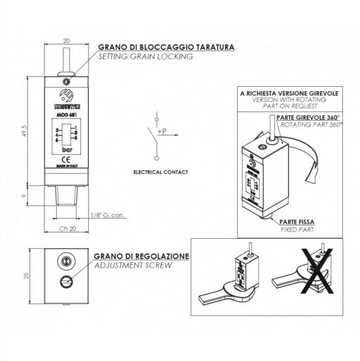

- Pressure Switch with Adjustment Knob

- SPDT C/O Contacts

- Up to 400 bar adjustment ranges

- Max over-pressure 900 bar

- Up to ≤ 250V / DIN43650

- Manifold / 1/4” BSP female (ES-692)

- NBR+Teflon seal

- ± 2% Tolerance across the range

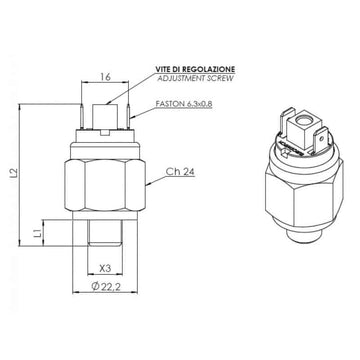

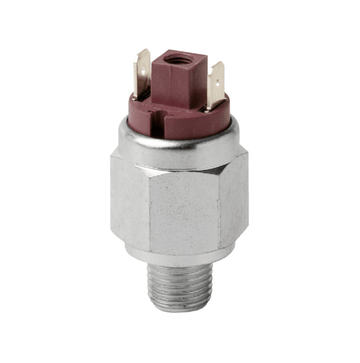

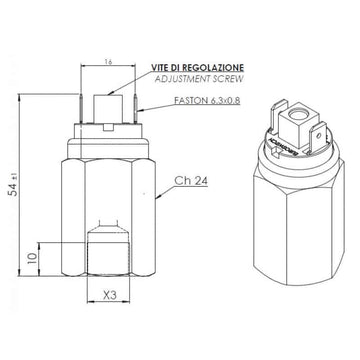

- Piston Pressure Switch ≤ 48V

- N/O or N/C Contacts

- Up to 300 bar adjustment ranges

- Over-pressures up to 800 bar

- Max working pressures up to 450 bar

- 1/4” BSP thread (others available)

- NBR+Teflon piston seal

- Steel or stainless steel body

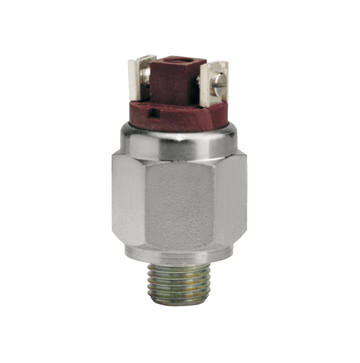

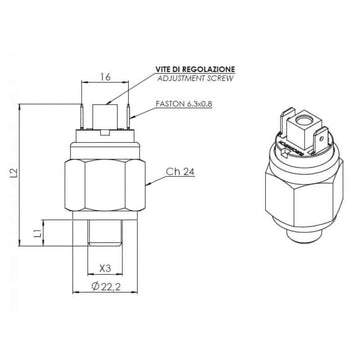

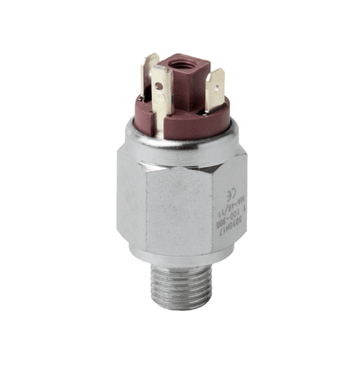

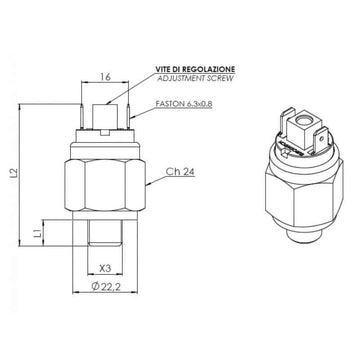

- Piston Pressure Switch ≤ 250V

- SPDT C/O Contacts

- Up to 400 bar adjustment ranges

- Over-pressures up to 900 bar

- Max working pressures up to 450 bar

- 1/4” BSP thread (others available)

- NBR+Teflon piston seal

- ATEX option available

- Diaphragm Pressure Switch ≤ 48V

- Female Thread N/O or N/C Contacts

- Up to 50 bar adjustment ranges

- Over-pressures up to 300 bar

- Max working pressures up to 150 bar

- 1/4” BSP female (others available)

- Viton seal (others available)

- Brass, steel or stainless steel body

- Temperature range: Ambient temperature from –20°C to +85°C

- Diaphragm material: NBR, Silicone, FKM (Viton® ), EPDM.

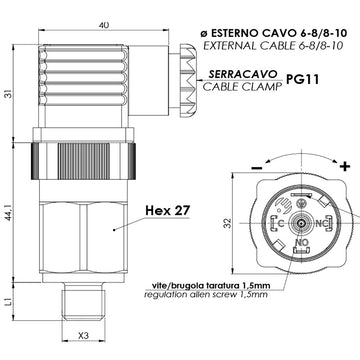

- Piston Pressure Switch ≤ 250V

- N/O or N/C Contacts

- Up to 300 bar adjustment ranges

- Over-pressures up to 800 bar

- Max working pressures up to 450 bar

- 1/4” BSP thread (others available)

- NBR+Teflon piston seal

- Steel or stainless steel body

- Pressure Switch ≤ 250V

- SPDT C/O Contacts

- Up to 300 bar adjustment ranges

- Over-pressures up to 800 bar

- Max working pressures up to 450 bar

- 1/4” BSP thread (others available)

- Viton / NBR+Teflon Seal (Model 28N)

- Adjustable Hysterisis (10-50%)

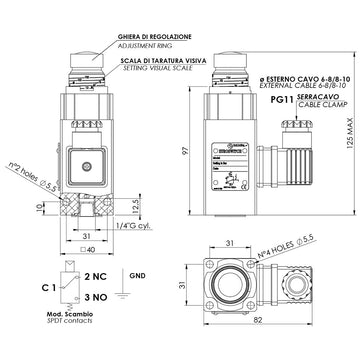

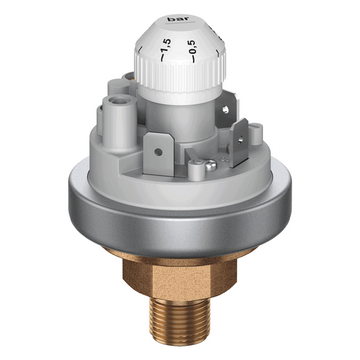

- Pressure Switch with Visual Scale

- SPST N/O Contacts

- Up to 6 bar adjustment ranges

- Max over-pressure 20 bar

- Switch rating 48V

- Air only

- Electrical cable (Model. 681)

- DIN43650 (Model. 682)

- Current Rating: 0.2-5 A

- Media Type: Liquid

- Contact System Type: SPDT

- Accuracy: +/- 1% FSR

- Min Range: 5 bar

- Max Range: 400 bar